How to Choose the Right Heavy Equipment for Your Construction Needs

In the ever-evolving construction industry, selecting the right heavy equipment is crucial for maximizing efficiency and ensuring project success. According to a report by the International Equipment Management Association, the heavy equipment market is projected to reach USD 200 billion by 2025, reflecting a growing demand for advanced machinery that can enhance productivity on job sites. This burgeoning market underscores the importance of understanding the specific needs of a project when procuring equipment heavy equipment.

Effective decision-making in this regard is enhanced by thorough analysis and consideration of various factors, including soil type, project scale, and machinery capabilities. A study from the Construction Industry Institute reveals that improper equipment selection can lead to cost overruns of 10-15%, emphasizing the need for informed choices. Additionally, advancements in technology, such as telematics and machine learning, offer operators greater insights into equipment performance, which can further aid in making the right selections to fit dynamic construction needs. As the construction landscape continues to grow, so does the necessity for managers to be well-versed in the intricacies of heavy equipment selection, thus ensuring optimal resource utilization.

Understand Your Project Requirements and Specifications

When selecting heavy equipment for your construction project, understanding your project requirements and specifications is crucial. Begin by evaluating the scope and scale of your project. Consider factors such as the type of construction—whether it’s residential, commercial, or industrial. Each category may demand different capabilities and functionalities from the equipment, which will directly influence the efficiency of your operations.

For instance, a site requiring extensive earthmoving may need excavators and bulldozers, while a project focused on lifting heavy materials may require cranes or fork trucks.

Additionally, assess the specific terrain and environment where the construction will take place. Variables such as soil type, slope, and accessibility can greatly affect the suitability of certain equipment. If you are working in a confined space, smaller, more maneuverable machinery might be necessary. Furthermore, it’s important to consider the load capacities and reach of the equipment to ensure it meets the demands of the tasks at hand. By thoroughly analyzing these specifications and requirements, you can make an informed decision that enhances productivity and safety throughout the construction process.

Evaluate the Types of Heavy Equipment Available

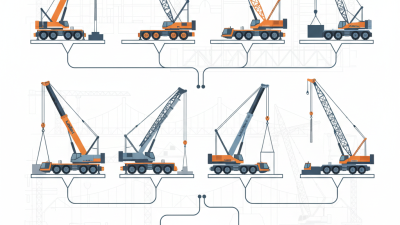

When evaluating the types of heavy equipment available for construction needs, it's essential to consider the specific tasks at hand. Different pieces of machinery serve distinct purposes, from earthmoving and lifting to material handling and demolition. For instance, excavators are ideal for digging foundations and removing soil, while bulldozers excel in pushing large quantities of material and leveling surfaces. Similarly, cranes are indispensable for lifting heavy loads to heights that manual labor cannot achieve.

In addition to task suitability, factors such as site conditions, available space, and equipment size must also be taken into account. Compact equipment may be more effective in limited spaces where maneuverability is crucial, such as urban construction sites. Conversely, larger machinery might be necessary for expansive projects requiring substantial earthmoving capabilities. Assessing the intended application, site characteristics, and equipment dimensions can help in selecting the most appropriate heavy equipment, ensuring efficiency and safety throughout the construction process.

Heavy Equipment Types for Construction Needs

Assess Equipment Performance, Capabilities, and Safety Features

When selecting heavy equipment for construction projects, assessing equipment performance, capabilities, and safety features is crucial. Performance can be measured by factors such as load capacity, operating speed, and fuel efficiency. It's essential to match the equipment with the specific demands of the project to ensure maximum productivity. For instance, a piece of machinery that offers higher lifting power or faster cycle times can dramatically influence the overall timeline of a construction project.

Equally important are the safety features integrated into the equipment. Modern machinery should comply with industry safety standards and come equipped with features like rollover protection, warning alarms, and emergency shut-off systems. Evaluating the safety records and user reviews can provide insights into prevalent issues and the reliability of safety mechanisms. Additionally, training operators on proper equipment use is vital to minimizing risk and ensuring a safe work environment. By prioritizing performance and safety, construction managers can make informed decisions that lead to successful project outcomes.

| Equipment Type | Performance Rating | Max Load Capacity (tons) | Capabilities | Safety Features |

|---|---|---|---|---|

| Excavator | 8.5/10 | 25 | Digging, Lifting, Grading | Automatic Shut-off, Rollover Protection |

| Bulldozer | 9/10 | 30 | Pushing, Grading, Clearing | Blade Guards, Operator Protection |

| Forklift | 8/10 | 10 | Lifting, Moving, Stacking | Overload Protection, Stability Control |

| Crane | 9.5/10 | 50 | Lifting, Hoisting | Load Limit Indicator, Anti-Tipping |

| Loader | 8.7/10 | 15 | Loading, Transporting | Safety Lights, Visibility Enhancements |

Consider Budget Constraints and Operational Costs

When selecting heavy equipment for construction projects, it is essential to consider budget constraints and operational costs to ensure long-term efficiency and profitability. Start by evaluating the total cost of ownership, which includes the initial purchase price, maintenance expenses, fuel consumption, and any insurance fees. Understanding these factors allows you to make informed decisions that align with financial capacities and project expectations.

Operational costs can fluctuate significantly based on equipment type and usage frequency. For instance, some machines may require specialized operators or incur higher maintenance fees due to their complexity. Analyzing the project's scope and duration can help identify the most cost-effective solutions. Renting equipment for short-term needs often proves more economical than purchasing outright, freeing up capital for other essential expenditures. Additionally, evaluating the potential resale value of the equipment can offer insights into its overall value, guiding you toward choices that maintain financial viability over time.

Plan for Maintenance and Support Services After Purchase

When selecting heavy equipment for construction projects, one of the most critical yet often overlooked considerations is the planning for maintenance and support services post-purchase. According to a report by the Association of Equipment Manufacturers, approximately 70% of construction companies cite the reliability and availability of maintenance services as a key factor in their purchasing decisions. This finding underscores the importance of selecting equipment that not only meets project requirements but also comes with robust after-sales support.

To ensure longevity and optimal performance of heavy machinery, companies should invest in equipment that offers comprehensive maintenance plans. A study from the Construction Industry Institute indicated that proper maintenance can extend the life of machinery by up to 50%, which translates to significant cost savings over time. Companies must evaluate the accessibility of service centers and the availability of replacement parts before making a purchase. Additionally, establishing a proactive maintenance schedule can dramatically reduce downtime and improve operational efficiency. By prioritizing maintenance and support services, construction managers can safeguard their investments and enhance productivity across their projects.

Related Posts

-

What is Construction Equipment Machine? Types, Uses, and Benefits Explained

-

10 Essential Tips to Find the Best Link Belt Dealer Near You

-

Top 10 Link Belt Equipment Options for Your Construction Needs

-

Why Choosing the Right Link Belt Crane Parts Dealer Matters for Your Projects

-

Finding the Best Link Belt Parts Dealer for Quality Service and Parts

-

Top 10 Link Belt Crane Dealers You Should Consider for Your Next Project

Subscribe to our newsletter.