How to Choose the Best Logging Equipment for Your Needs

When considering the best logging equipment for your needs, it is essential to reflect on various factors that cater to both operational efficiency and safety. The logging industry has witnessed significant growth, with reports indicating that the global logging equipment market is projected to reach approximately $9 billion by 2025, driven by increasing demand for timber and advancements in technology. Understanding the diverse types of logging equipment available, such as feller bunchers, skidders, and chainsaws, is crucial for optimizing productivity and minimizing environmental impact.

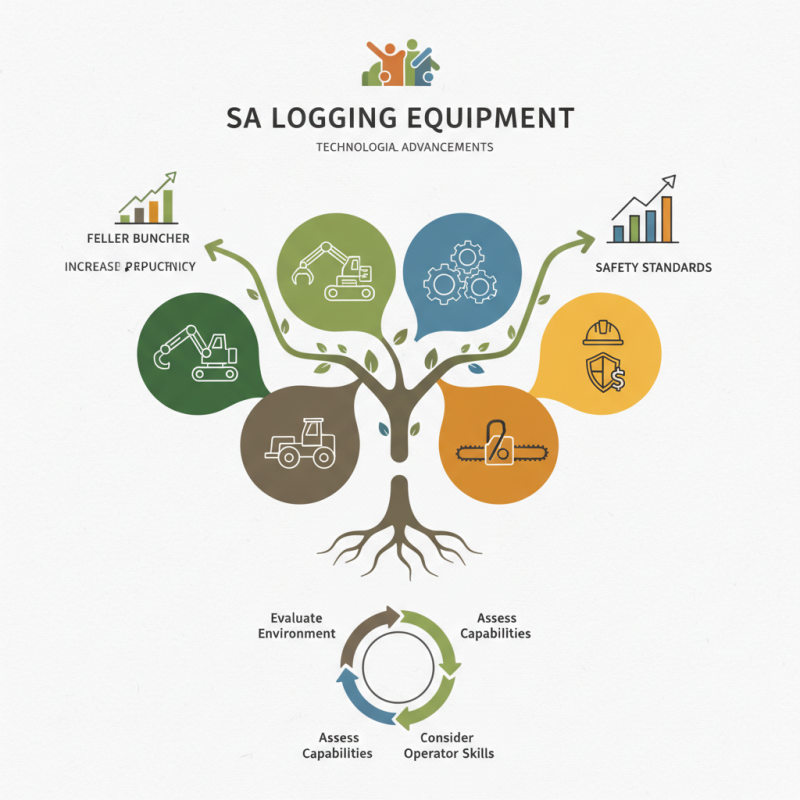

Moreover, industry experts emphasize the importance of selecting equipment that not only meets the specific requirements of the task but also complies with safety standards and regulations. According to studies, improper equipment selection can lead to up to 50% higher operational costs and increased accident rates in forestry operations. Therefore, evaluating your unique logging environment, assessing equipment capabilities, and considering operator skill levels are key to making informed decisions that enhance both performance and safety. In this guide, we will explore how to effectively choose logging equipment tailored to your specific needs, ensuring that you make an investment that pays off in the long run.

Understanding Different Types of Logging Equipment Available in the Market

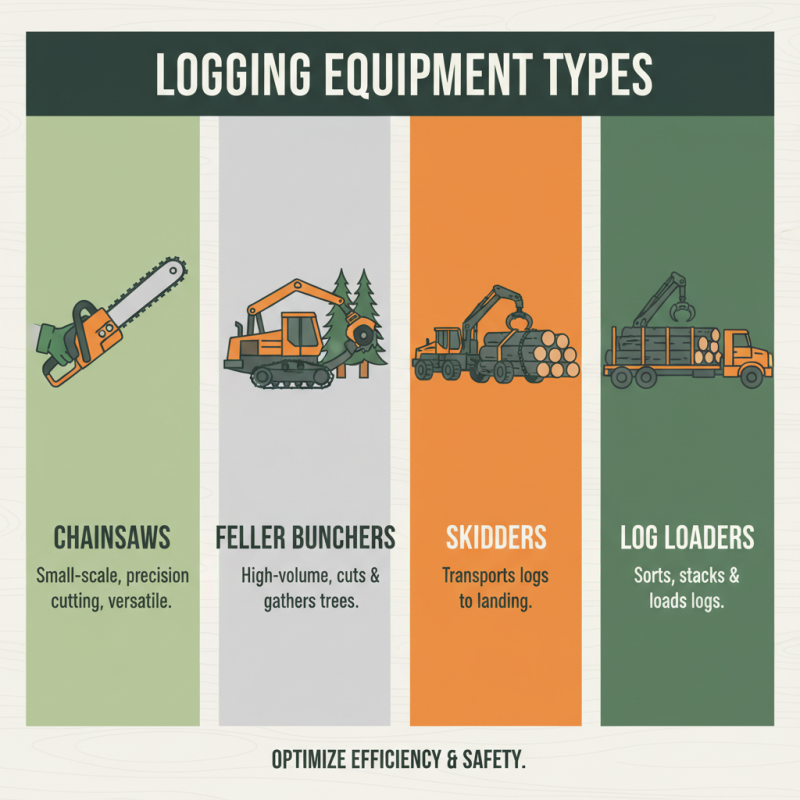

When selecting logging equipment, it’s important to understand the various types available in the market. Each type of equipment serves a specific purpose and can greatly impact efficiency and safety in logging operations. Common categories include chainsaws, feller bunchers, skidders, and log loaders. Chainsaws are versatile tools suitable for small-scale operations, allowing for precision cutting in difficult terrains. Feller bunchers, on the other hand, streamline the process by cutting and gathering multiple trees at once, making them ideal for larger logging projects.

In addition to these primary tools, auxiliary equipment plays a crucial role in supporting logging tasks. For instance, chippers are used to convert scraps into mulch, while forwarders assist in transporting logs from the felling site to processing locations. Each type of equipment has distinct features, such as size, power, and functionality, which should align with the specific logging needs and the scale of the operation. Understanding these options can help loggers make informed decisions, ensuring they choose the best equipment for their requirements.

Assessing Your Specific Logging Needs and Requirements

When selecting logging equipment, it is crucial to assess your specific logging needs and requirements. Begin by evaluating the type of logging you intend to undertake—whether it is commercial logging, small-scale timber harvesting, or land clearing for development. Each operation demands different equipment characteristics, such as power, mobility, and efficiency. Understanding the scale of your project will help dictate the size and capability of the machinery you need, ensuring that you choose equipment that can handle the volume and type of material effectively.

Next, consider the terrain and environment where the logging will occur. Different terrains present unique challenges, requiring specialized equipment. For instance, if you are working in steep or rugged landscapes, look for machines with better traction and stability features. Additionally, evaluate your workforce’s expertise and safety requirements; some equipment may require skilled operators or safety training. By outlining your specific logging conditions and resources, you can make more informed decisions, ensuring that you select equipment that not only meets your operational needs but also promotes safety and efficiency throughout the logging process.

How to Choose the Best Logging Equipment for Your Needs

| Equipment Type | Primary Use | Capacity / Power | Weight | Price Range |

|---|---|---|---|---|

| Chainsaw | Felling Trees | 40cc - 120cc | 5 - 12 lbs | $200 - $800 |

| Log Splitter | Splitting Logs | 5 - 30 tons | 100 - 300 lbs | $400 - $3000 |

| Skid Steer | Moving Logs | 20 - 50 hp | 2500 - 4000 lbs | $20,000 - $60,000 |

| Wood Chipper | Chipping Branches | 5 - 15 hp | 200 - 800 lbs | $300 - $5000 |

| Feller Buncher | Cutting & Gathering Trees | 100 - 200 hp | 12,000 - 18,000 lbs | $200,000 - $500,000 |

Factors to Consider When Choosing Logging Equipment

When choosing logging equipment, there are several critical factors to consider to ensure that you select the best tools for your specific needs. First and foremost, assess the type of logging operation you will be conducting—whether it's clear-cutting, selective logging, or thin harvesting. Each method requires different equipment characteristics. According to a report by the Forest Products Laboratory, the efficiency of logging operations can be improved by nearly 30% when using equipment specifically suited to the logging method employed.

Another crucial factor is the terrain and climate in which the equipment will be used. Steep or rugged landscapes may necessitate specialized machines such as grapples and feller bunchers designed to navigate these challenging environments effectively. In contrast, flat terrain might accommodate different types of harvesters. A study by the U.S. Forest Service indicates that appropriate equipment selection for site conditions can significantly reduce operational downtime and maintenance costs by up to 20%.

Tip: When evaluating logging equipment, consider investing in machines with greater versatility, allowing you to adapt to various logging tasks without needing multiple specialized tools. Additionally, ensure that the equipment meets safety standards to protect operators during logging operations. Regular training on equipment handling and safety protocols cannot be overstated; it is crucial for maximizing both productivity and safety on the job site.

Budgeting for Your Logging Equipment Purchase

When planning to purchase logging equipment, budgeting is a critical consideration that can significantly influence your choices. Start by assessing your overall financial situation and determining how much you can allocate for this purchase. Consider not only the initial costs but also any additional expenses that may arise, including maintenance, repairs, and operation costs. This holistic view ensures you don’t overlook ongoing expenses that could strain your budget in the long run.

Next, prioritize your needs to help guide your spending. Identify the specific equipment that is essential for your logging operations and rank them based on importance and frequency of use. This method allows you to make informed decisions about where to invest your budget most effectively. Additionally, it’s wise to research financial options such as financing plans or leasing alternatives that can spread out expenses, making it easier to manage cash flow while still acquiring the necessary tools for your work.

By keeping these budgeting strategies in mind, you’ll be better equipped to make a purchase that aligns with your operational needs and financial capabilities.

Maintenance and Support for Logging Equipment Post-Purchase

When investing in logging equipment, maintenance and support are crucial factors that can significantly affect the longevity and performance of your machinery. Understanding how to care for your equipment is essential to avoid costly repairs and downtime. Regular maintenance routines should include checking and replacing wear parts, lubricating moving components, and verifying safety systems are functioning correctly. Establishing a maintenance schedule can help keep equipment in optimal condition, reducing the risk of unexpected breakdowns during critical operational periods.

Moreover, having access to reliable support and service post-purchase is indispensable. Consider the availability of technical assistance from the supplier, as well as the accessibility of spare parts and replacement components. A good support system will ensure you can quickly address any issues that arise, which is vital for maintaining productivity on the job site. Training programs for operators and maintenance personnel can also be a valuable resource, as they equip your team with the knowledge necessary to handle equipment effectively and troubleshoot minor issues on their own. Prioritizing both maintenance and support can lead to greater efficiency and a longer lifespan for your logging equipment.

Logging Equipment Maintenance Frequency

Related Posts

-

Top 10 Tips for Buying High Quality Construction Used Equipment

-

10 Essential Tips to Find the Best Link Belt Dealer Near You

-

Top 10 Tips for Finding Reliable Link Belt Parts Dealers Near You

-

Why Investing in Modern Construction Equipment and Machinery is Essential for Your Success

-

Top 10 Link Belt Equipment Options for Your Construction Needs

-

Why Investing in Forestry Equipment Is Essential for Sustainable Forest Management

Subscribe to our newsletter.