10 Essential Tips for Using a Link Belt Machine Effectively

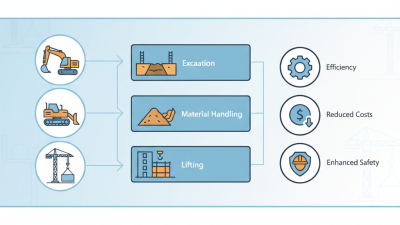

In the construction and manufacturing sectors, the link belt machine plays a crucial role. According to a recent market analysis, these machines increase productivity by up to 20%. They are vital for handling materials efficiently. Proper use of a link belt machine can significantly impact project timelines and costs.

Yet, many operators overlook essential practices. Studies reveal that improper operation can lead to equipment malfunctions and downtime. Training is often inadequate, resulting in a lack of understanding of machine capabilities. Without proper knowledge, even the best link belt machines can underperform.

There is always room for improvement. Operators should regularly assess their techniques and seek feedback. Mistakes are part of the learning process, and recognizing them is key to mastering the link belt machine's potential. Emphasizing training and best practices can lead to better outcomes.

Understanding the Basics of Link Belt Machines and Their Components

Link belt machines are vital in many industries. Understanding their basic components is essential for effective use. These machines typically consist of a belt, pulleys, and a drive mechanism. Each part plays a significant role in the overall function. The belt transfers power efficiently, while pulleys help in changing direction and speed. Regular maintenance is crucial to ensure optimal performance.

Data indicates that improper maintenance can lead to a 20% drop in efficiency. This shows the importance of routine checks. For instance, belt tension should be monitored closely. If too loose or too tight, it can cause premature wear. Additionally, lubrication of moving parts must not be neglected. A recent report highlighted that 15% of system failures are due to inadequate lubrication practices.

Operators must also be aware of the load limits. Exceeding the max capacity can damage the machine. This is often overlooked in high-pressure environments. Understanding the load requirements can prevent accidents and enhance safety. A detailed analysis of operational data can help identify patterns in machine usage. Monitoring these factors is crucial for longevity and efficient performance.

Choosing the Right Link Belt Machine for Your Project Needs

When selecting a link belt machine for a project, it's essential to analyze the specific requirements. Various projects demand different specifications. Choosing a machine based on empirical data can lead to better outcomes. According to industry reports, approximately 70% of project inefficiencies stem from improper equipment selection. Understanding your project's load capacity, speed, and environmental conditions can greatly influence performance.

Consider the material being handled. Materials vary in weight and size, which affects the type of link belt machine needed. For example, handling heavy materials may require machines with higher tensile strength. A survey by the Machinery and Equipment Manufacturers Association indicates that using the wrong machine can increase operational costs by up to 30%. This highlights the importance of informed decision-making.

Additionally, the environment plays a crucial role. Machines used outdoors may need enhanced durability against elements. In fact, studies show that 60% of machinery breakdowns are due to environmental factors. Ensuring the right choice for each project not only boosts efficiency but also reduces maintenance issues. Reflecting on these considerations can lead to significant improvements in project execution.

10 Essential Tips for Using a Link Belt Machine Effectively

This chart illustrates the effectiveness ratings for each of the 10 essential tips for using a Link Belt machine effectively. Each tip was rated on a scale from 1 to 10, assessing how well it contributes to the successful operation of the machine.

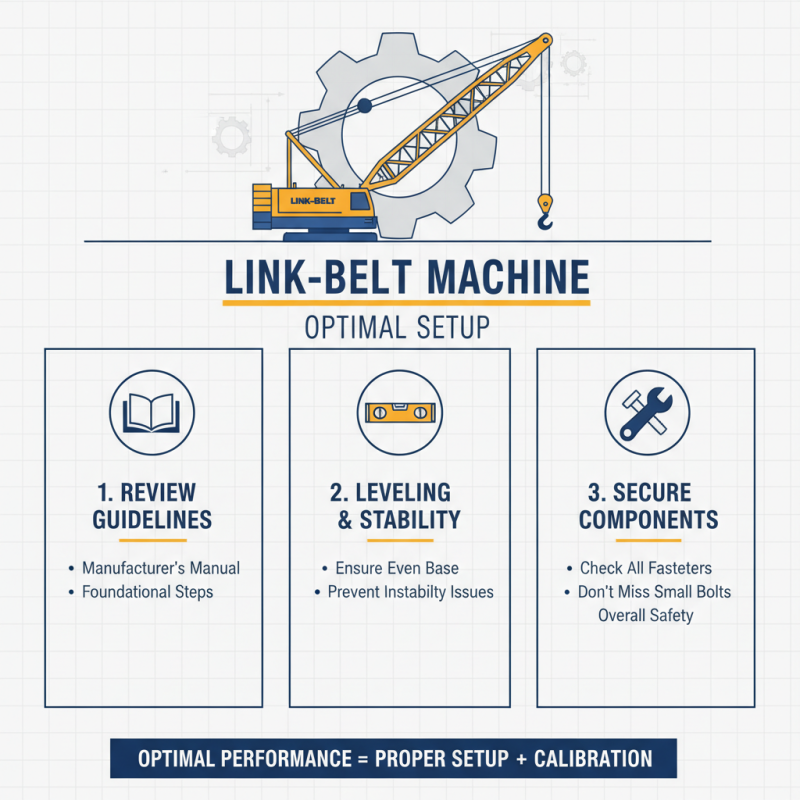

Essential Setup and Calibration Procedures for Optimal Performance

Setting up and calibrating a Link Belt machine is crucial for optimal performance. Begin by reviewing the manufacturer's guidelines. These instructions offer foundational steps for proper setup. Pay close attention to leveling the machine; an uneven base can lead to stability issues. Check if all components are securely fastened. It is easy to overlook small bolts, but they play a significant role in overall safety.

Calibration is another pivotal step. It may take more time than expected, and that's okay. Use a calibration tool to ensure accuracy in measurements. Mistakes during calibration can result in operational errors. Regularly verify your machine's settings and adjust them as needed. A little time spent here can save hours of troubleshooting down the line.

Maintaining a clean work area can enhance the machine's efficiency. A cluttered space can lead to accidents and delays. Check for debris that might get caught in moving parts. Reflections on past mistakes can guide better practices. Perhaps a previous neglect in these areas led to issues; recognize this and move forward with diligence.

Safety Best Practices When Operating a Link Belt Machine

Operating heavy machinery requires a strong focus on safety. Reports indicate that nearly 70% of workplace accidents involve machinery. This statistic highlights the importance of following safety best practices when using any construction equipment, including a link belt machine. Before starting, operators should conduct a thorough inspection. Check for loose parts, leaks, and proper fluid levels. A small oversight can lead to significant hazards.

Personal protective equipment (PPE) is essential. Hard hats, gloves, and steel-toed boots reduce the risk of injury. Studies show that wearing appropriate PPE can prevent up to 30% of injuries caused by heavy equipment. Additionally, clear communication among team members is vital. Use hand signals and two-way radios to avoid misunderstandings. These practices ensure everyone is aware of the machine’s movements.

Training is crucial for operators. A study found that 25% of accidents occur due to inadequate training. Proper education on the machine's functions and safe operation significantly reduces risks. Encourage continuous learning and refresh training regularly. This proactive approach creates a culture of safety, fostering responsible operation among all employees involved with heavy machinery.

10 Essential Tips for Using a Link Belt Machine Effectively - Safety Best Practices When Operating a Link Belt Machine

| Tip | Description | Frequency of Use | Importance Level |

|---|---|---|---|

| Perform Regular Inspections | Check the machine for any signs of wear or damage before operation. | Daily | High |

| Use Proper PPE | Always wear helmets, gloves, and protective eyewear. | Always | High |

| Follow Operating Instructions | Adhere strictly to the user manual and guidelines. | Every Use | Critical |

| Maintain a Safe Distance | Keep non-operators at least a safe distance away while the machine is in use. | Always | High |

| Keep Work Area Clean | Ensure the work area is free of debris to prevent accidents. | Daily | Moderate |

| Plan Lifts Ahead of Time | Pre-plan the lifting tasks to avoid surprises during operation. | Before Each Task | High |

| Check Load Limits | Understand and respect the load limits of the machine for safety. | Every Use | Critical |

| Stay Alert and Focused | Avoid distractions and stay focused on the work at hand. | Always | High |

| Emergency Procedures | Know the emergency procedures and how to shut down the machine quickly. | Monthly Review | Critical |

Regular Maintenance and Troubleshooting Tips for Longevity

Regular maintenance is crucial for extending the lifespan of your Link Belt machine. Checking fluid levels, such as hydraulic oil, should be a routine task. This ensures the machine operates smoothly.

Dirty filters can affect performance. Clean or replace them regularly to maintain efficiency.

Another vital aspect is inspecting components for wear and tear. Look closely at belts, hoses, and pins. Signs of damage can lead to significant issues later.

Replace any part that seems questionable to avoid unexpected downtime. Document these checks; it helps track maintenance history.

Don't overlook troubleshooting. When a problem arises, narrow it down systematically.

Listen for unusual sounds; they often indicate mechanical issues. Observe the machine’s response during operation. Any irregularity can signal an underlying issue.

Address these problems early to prevent costly repairs. Remember, prompt action is essential for longevity.

Related Posts

-

How to Choose the Right Link Belt Machine for Your Construction Needs

-

Why Choose Link Belt Company for Your Material Handling Solutions?

-

10 Essential Tips to Find the Best Link Belt Dealer Near You

-

How to Choose the Right Heavy Equipment Company for Your Project Needs

-

What is Construction Equipment Machine? Types, Uses, and Benefits Explained

-

2026 Top Heavy Machinery Dealer Trends and Innovations?

Subscribe to our newsletter.