Why Investing in Equipment Machines is Essential for Business Success?

Investing in equipment machines is crucial for business growth. According to market research, companies that leverage advanced machinery enjoy a productivity boost of up to 30%. This increase is not just a statistic; it's a tangible advantage in competitive industries. Additionally, 75% of businesses that upgrade their equipment report a significant decrease in operational costs.

Yet, many firms hesitate to invest in modern machinery. They fear the upfront costs or the complexity of installation. These concerns can hinder potential growth, leading to lost opportunities. Companies using outdated equipment often face slower production rates and higher maintenance costs. Investing in equipment machines could mitigate these risks.

In today's fast-paced market, businesses need to adapt swiftly. Those that fail to integrate innovative machinery might fall behind competitors. Industry studies show that 60% of successful enterprises consistently reinvest in their equipment. This trend highlights the importance of continual investment for long-term success. Ignoring equipment machines can lead to stagnation and missed growth prospects.

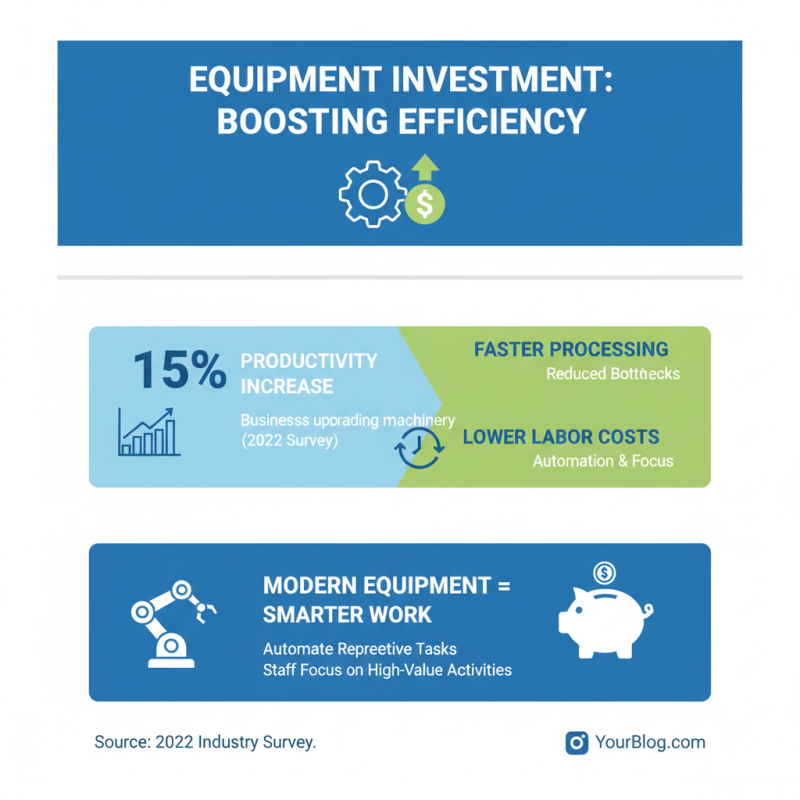

Importance of Equipment in Enhancing Operational Efficiency

Investing in equipment machines plays a crucial role in enhancing operational efficiency. According to a 2022 industry survey, businesses that upgraded their machinery saw a 15% increase in productivity. This improvement often stems from faster processing times and reduced labor costs. Modern equipment can automate repetitive tasks, allowing staff to focus on high-value activities.

However, the investment in equipment also comes with challenges. Over 30% of businesses reported delays in equipment procurement, leading to operational bottlenecks. Additionally, poorly maintained machines can lead to increased downtime, with an average cost of $500 per hour lost. It’s essential to find a balance between cutting-edge technology and practical implementation. Without the right strategies, companies may find their investments yielding less than expected.

Furthermore, training staff to effectively use new machinery is vital. A study revealed that 45% of operational inefficiencies arise from inadequate training. Properly trained employees can maximize the potential of new equipment, fostering an environment of continuous improvement. Businesses must recognize that investing in equipment is not just about the machines themselves; it’s also about the people who operate them.

Impact of Advanced Machinery on Product Quality and Consistency

Advanced machinery plays a crucial role in enhancing product quality. Precision tools create consistent results. This leads to fewer defects and improved customer satisfaction. When equipment is reliable, the production process becomes smoother. Companies can meet demands more effectively.

Investing in modern machines often requires significant financial commitment. However, the payoff can be substantial. For instance, automation reduces manual errors. It also accelerates production times. Yet, some businesses hesitate due to the initial costs. They worry about the return on investment.

Upgrading machinery can bring unforeseen challenges. Staff may need retraining to operate new equipment. This can disrupt workflow temporarily. Regular maintenance is essential to prevent downtime. Therefore, businesses must weigh pros and cons carefully. Balancing quality improvements with operational costs is crucial for long-term success.

Why Investing in Equipment Machines is Essential for Business Success? - Impact of Advanced Machinery on Product Quality and Consistency

| Machine Type | Impact on Quality | Impact on Consistency | Investment Cost | ROI (Return on Investment) |

|---|---|---|---|---|

| CNC Machine | High precision in manufacturing | Consistent output quality | $100,000 | 25% annually |

| Printing Press | Enhanced color accuracy | Uniform print quality | $80,000 | 20% annually |

| Robotic Arm | High-speed assembly with precision | Stable production rate | $150,000 | 30% annually |

| Laser Cutter | Precision cutting edges | Reliable quality standards | $120,000 | 22% annually |

| Injection Molding Machine | High-quality plastic parts | Enhanced product uniformity | $200,000 | 28% annually |

Cost-Benefit Analysis of Investing in New Equipment

Investing in new equipment machines can significantly impact a business's financial health. The initial costs may seem daunting. However, conducting a thorough cost-benefit analysis reveals potential advantages. For instance, new machines can boost production efficiency. This means less downtime and quicker output. Enhanced precision also leads to fewer errors. In many cases, these factors translate to higher profits over time.

Consider the long-term savings that come with energy-efficient machines. They often reduce utility bills, benefiting the bottom line. Assessing maintenance costs is crucial as well. Older equipment may require frequent repairs and lead to unexpected expenses. If you find that repairs outweigh the costs of a new purchase, it's time for a change. Yet, investing isn't without risks. Market conditions can shift, and the return on investment might not be immediate.

Some businesses hesitate due to fear of overextending their budgets. This hesitation can be counterproductive. Setting a well-defined budget and projecting future cash flows can ease such concerns. Understanding the potential for greater productivity is key. Miscalculating these factors could lead to losses instead of gains.

Role of Technology in Driving Competitive Advantage

Investing in equipment machines is pivotal to achieving business success. Technology propels businesses forward, enhancing productivity and efficiency. Cutting-edge machines streamline operations and reduce human error. For instance, automated systems can manage inventory with precision. This not only saves time but also minimizes waste. In an age where speed matters, outdated machines can hinder progress.

However, it’s essential to consider the costs involved. High-quality machines require significant investment. Companies often face the challenge of balancing cost and technology. Some may invest in state-of-the-art equipment only to realize they lack the training to use it fully. A machine without skilled operators is like a car without a driver. This gap often leads to underperformance and missed opportunities.

Moreover, technology can create dependency. Businesses might focus too heavily on machines, neglecting human creativity. While machines enhance efficiency, they cannot replace innovative thinking. A balance between technology and human input is crucial. Companies should reflect on their strategies regularly. Improvement is a continuous journey that requires adaptation to the evolving landscape.

Long-Term Benefits of Equipment Investment for Business Growth

Investing in equipment machines can lead to significant long-term benefits for businesses. Newer machines often perform tasks more efficiently. This increased efficiency can reduce operation time and costs. For instance, a modern machine may cut production time in half. This means more output and potentially higher profits.

However, investing in equipment isn’t always a smooth process. Companies must assess their needs carefully. Choosing the wrong equipment can lead to wasted resources. Maintenance costs also rise with older machines. These challenges can create obstacles in the short term. Yet, with proper planning, advantages accumulate over time.

Long-term equipment investment can also enhance workforce productivity. Employees may feel empowered using better tools. Motivation often increases when workers have access to modern equipment. On the flip side, if they struggle with outdated technology, frustration builds. A well-chosen investment can foster a positive workplace atmosphere, leading to growth and innovation.

Related Posts

-

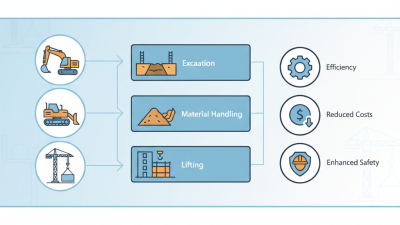

How to Choose the Right Heavy Equipment for Your Construction Needs

-

Top 10 Link Belt Equipment Options for Your Construction Needs

-

How to Choose the Right Link Belt Machine for Your Construction Needs

-

What is Construction Equipment Machine? Types, Uses, and Benefits Explained

-

Top Equipment Machines to Watch in 2025 for Increased Efficiency and Productivity

-

What is a Link Belt Parts Dealer and How to Choose One?

Subscribe to our newsletter.