Top Equipment Machines to Watch in 2025 for Increased Efficiency and Productivity

In the rapidly evolving landscape of industrial operations, the importance of advanced equipment machines cannot be overstated. As businesses strive to enhance efficiency and productivity, investing in cutting-edge technology has become paramount. According to a report from the International Federation of Robotics, the global market for industrial robots is expected to grow at a compound annual growth rate (CAGR) of 10.5% from 2021 to 2026, underscoring the increasing reliance on sophisticated machinery to streamline processes and improve output.

Moreover, a study by McKinsey highlights that automation and artificial intelligence could potentially elevate productivity in manufacturing by up to 30% in the next decade. This significant shift is driven by the emergence of innovative equipment machines that leverage smart technology to optimize production cycles, reduce downtime, and enhance overall operational effectiveness. As we look towards 2025, it is imperative for organizations to stay informed about the latest advancements in equipment machines to remain competitive and achieve sustainable growth in an increasingly automated world.

Emerging Trends in Equipment Machines for Enhanced Performance

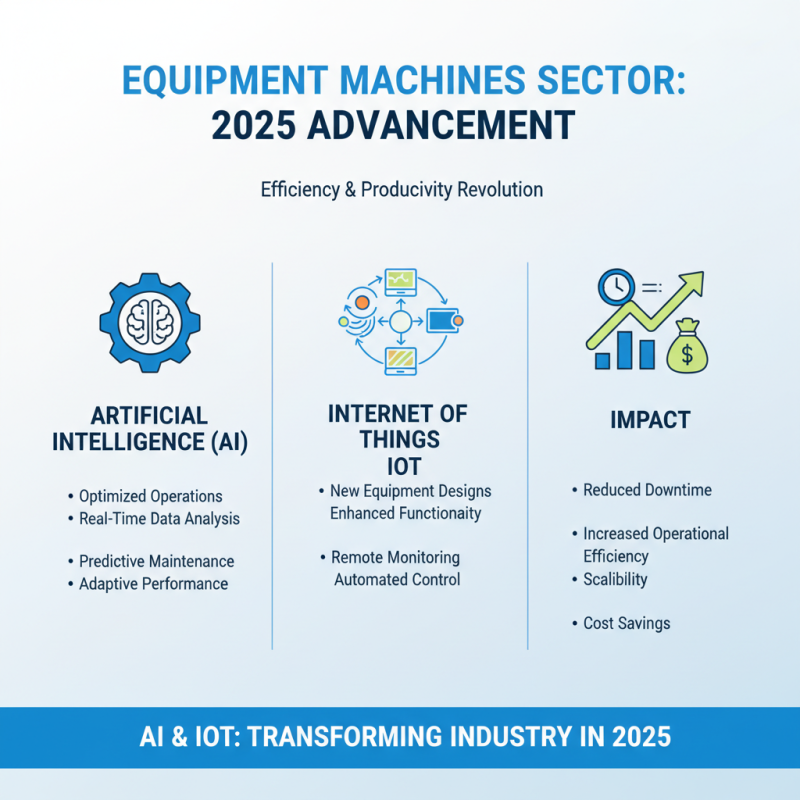

In 2025, the equipment machines sector is poised for transformative advancements that will significantly enhance efficiency and productivity. Emerging technologies such as artificial intelligence (AI) and the Internet of Things (IoT) are shaping new equipment designs and functionalities. Machines equipped with AI algorithms will optimize operations by analyzing real-time data, predicting maintenance needs, and adjusting performance based on workload fluctuations. This not only reduces downtime but also enhances overall operational efficiency, allowing businesses to scale their activities more effectively.

Another notable trend is the integration of sustainable practices in equipment design. As environmental considerations become more pressing, manufacturers are focusing on energy-efficient machines that minimize waste and reduce resource consumption. Innovations in materials and processes are yielding equipment that not only performs at higher levels but also adheres to sustainability standards. The adoption of modular systems allows for easier upgrades and repairs, ensuring that machines remain relevant and capable of meeting evolving production demands. These trends indicate a shift toward machines that not only contribute to productivity but also align with broader sustainable goals.

Key Features of Top Machines for Efficiency in 2025

In 2025, the landscape of equipment machines is set to undergo a significant transformation, focusing on efficiency and productivity. Key features that define the machines of the future will include advanced automation technologies, enhanced energy efficiency, and intelligent connectivity. Automation will not only streamline operations but also minimize human error, leading to higher accuracy in production processes. Energy-efficient designs will help companies reduce operational costs, making it essential for organizations to invest in machines that adhere to sustainability standards.

Tips for maximizing efficiency in 2025 include investing in machines that are equipped with IoT capabilities. These smart machines will enable real-time monitoring and data analysis, allowing businesses to make informed decisions quickly. Additionally, flexibility in machine design will be crucial; equipment that can adapt to various tasks and production needs will significantly improve workflow and reduce downtime.

Another essential feature to look for is user-friendly interfaces. As technology evolves, intuitive designs become paramount, allowing operators to easily understand and manage machine functions. Educating your workforce on these new technologies through proper training can also dramatically enhance productivity levels, ensuring that the full potential of the equipment is utilized effectively. Embracing these key features will be instrumental for businesses aiming to stay competitive in the rapidly changing market.

Innovative Technologies Driving Productivity in Equipment Design

The equipment industry is on the brink of a technological transformation, significantly impacting efficiency and productivity in 2025. Emerging technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and advanced robotics are driving innovative designs that optimize operations. According to a recent report by McKinsey & Company, companies integrating IoT into their machinery can see productivity gains of up to 20%, as these systems facilitate real-time monitoring and predictive maintenance, allowing for proactive decision-making.

Another critical advancement lies in the application of AI-driven analytics, which can enhance operational efficiency by identifying patterns and suggesting improvements. For instance, a study conducted by PwC highlighted that AI adoption in the manufacturing sector could potentially add $15.7 trillion to the global economy by 2030. This growth is attributed to increased efficiencies these technologies bring to equipment performance and workflow optimization. As machinery becomes smarter, manufacturers can expect not only reduced downtime but also improved user safety and resource management, further emphasizing the importance of these innovative solutions in the future landscape of equipment design.

Innovative Technologies Driving Productivity in Equipment Design

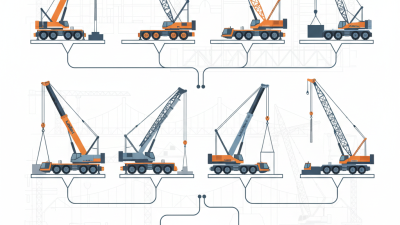

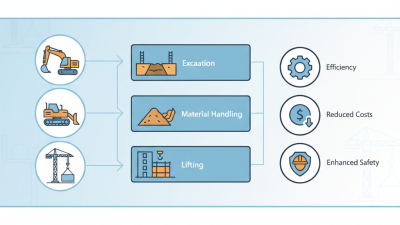

Sector-Specific Equipment Machines Gaining Traction in 2025

As we approach 2025, several sector-specific equipment machines are poised to revolutionize productivity and efficiency across various industries. In the manufacturing sector, automation continues to gain traction, with advanced robotics and modular systems designed to streamline production lines. These machines not only increase output but also enhance precision, reducing the margin for error—an essential factor in achieving high-quality standards. Furthermore, the integration of artificial intelligence into these systems allows for adaptive learning, which optimizes performance based on real-time data and operational feedback.

In agriculture, precision farming equipment is becoming increasingly vital. Machines equipped with technology such as drones and GPS-guided tools are helping farmers make informed decisions about crop management and resource allocation. This not only maximizes yields but also promotes sustainable practices by reducing waste and minimizing environmental impact. As sectors recognize the necessity of integrating innovative machinery, the trend towards eco-friendly, high-efficiency equipment is likely to dominate the landscape in 2025, driving both economic growth and environmental stewardship.

Future-Proofing Operations: Investment in Next-Generation Machinery

As industries evolve and face new challenges, future-proofing operations through strategic investments in next-generation machinery has become paramount. The landscape of manufacturing, logistics, and construction is poised for transformation, driven by advancements in technology such as automation, IoT integration, and AI applications. By prioritizing these innovations, companies can enhance their operational efficiency, reduce downtime, and streamline processes, thereby positioning themselves ahead of competitors.

Investing in cutting-edge equipment not only increases productivity but also addresses the ever-changing demands of the market. Companies that adopt advanced machinery are better equipped to respond to fluctuations in consumer behavior and supply chain dynamics. This adaptability ensures long-term sustainability, as businesses can pivot effectively in response to emerging trends. Moreover, next-generation machines often come with enhanced capabilities that reduce environmental impact, aligning operations with global sustainability goals, ultimately contributing to a brand's reputation and customer loyalty.

Top Equipment Machines to Watch in 2025 for Increased Efficiency and Productivity

| Machine Type | Key Features | Efficiency Improvement (%) | Productivity Gain (%) | Expected Adoption Year |

|---|---|---|---|---|

| Automated Excavator | AI-powered operation, remote control | 50% | 30% | 2025 |

| Smart Forklift | Integrated sensors, collision avoidance | 40% | 20% | 2025 |

| 3D Printing Machine | Rapid prototyping, material versatility | 35% | 25% | 2025 |

| Robotic Arm | High precision, adaptable tasks | 60% | 40% | 2025 |

| Drone Technology | Aerial mapping, real-time data | 45% | 35% | 2025 |

Related Posts

-

Top 10 Link Belt Crane Dealers You Should Consider for Your Next Project

-

Top 10 Link Belt Equipment Options for Your Construction Needs

-

What is Construction Equipment Machine? Types, Uses, and Benefits Explained

-

Why Investing in Modern Construction Equipment and Machinery is Essential for Your Success

-

Why Choosing the Right Link Belt Crane Parts Dealer Matters for Your Projects

-

How to Choose the Right Heavy Equipment for Your Construction Needs

Subscribe to our newsletter.