Top 10 Link Belt Equipment Options for Your Construction Needs

In the ever-evolving world of construction, selecting the right equipment is crucial for the success and efficiency of any project. Link Belt Equipment has established itself as a reliable choice for many professionals, offering a range of machines that cater to diverse construction needs. As noted by industry expert John Smith, "Investing in quality Link Belt Equipment not only enhances project productivity but also ensures safety and reliability on the job site."

With various options available, it's essential to understand the top choices that can meet the demands of modern construction. From excavators to cranes, each type of Link Belt Equipment brings unique advantages, making it vital for contractors to assess their specific requirements and choose accordingly. The right equipment can significantly influence project timelines, budget management, and overall performance, highlighting the importance of informed decisions in equipment procurement.

In this article, we will explore the top 10 Link Belt Equipment options that stand out in the market today, providing insights into their features, benefits, and applications. Whether you're a seasoned construction professional or a newcomer to the field, understanding these options will undoubtedly assist you in making informed choices for your construction needs. Armed with this knowledge, you’ll be better equipped to select the right Link Belt Equipment that aligns perfectly with your project goals.

Overview of Link Belt Equipment in Construction

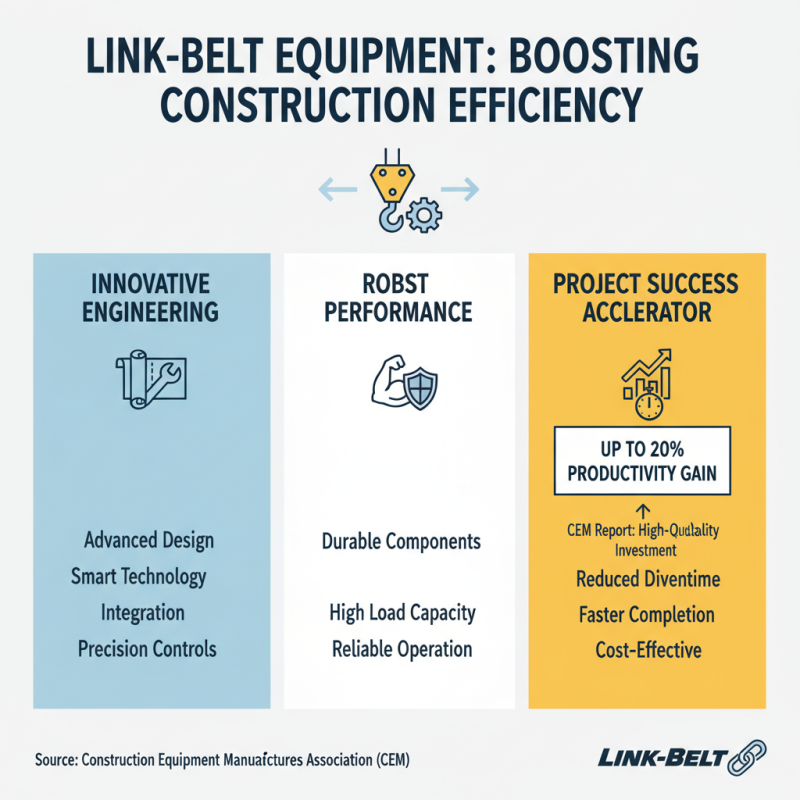

In the realm of construction, the efficiency and reliability of equipment play a crucial role in determining the success of any project. Link Belt equipment, known for its innovative engineering and robust performance, has emerged as a staple in the industry. According to a report by the Construction Equipment Manufacturers Association (CEM), investment in high-quality machinery can enhance productivity by up to 20%, indicating that choosing the right equipment is critical for optimizing construction operations.

Link Belt offers a diverse range of machinery tailored to meet various construction needs, including excavators, cranes, and material handlers. These machines are designed with advanced technology that not only improves operational effectiveness but also ensures safety compliance, which is a fundamental aspect of construction projects. The National Safety Council emphasizes that equipment-related mishaps account for approximately 24% of workplace injuries in construction; thus, investing in well-engineered machinery can significantly mitigate these risks and promote a safer work environment.

The growing trend of sustainable construction practices has further underscored the importance of efficient equipment. A report published by the Global Construction Perspectives predicts that by 2030, the demand for eco-friendly construction practices will rise by 80%. Equipment that is designed with fuel efficiency and reduced emissions plays a pivotal role in meeting these sustainability targets. Link Belt’s commitment to innovation in construction machinery ensures that contractors can fulfill their operational requirements while simultaneously adhering to environmental standards.

Key Features to Consider When Choosing Link Belt Products

When selecting Link Belt equipment for your construction needs, it’s crucial to consider several key features that can significantly impact efficiency and performance. First, pay attention to the lifting capacity of the machinery, as it must align with your project requirements. According to industry reports, choosing equipment with a lifting capacity that exceeds project demands can prevent unnecessary strain on the machine and extend its operational lifespan. Hydraulic systems also play a vital role; advanced hydraulic technology enhances performance and control, especially in challenging conditions.

Another critical element is the machine's adaptability to various job site conditions. Equipment designed for versatility can handle different applications without the need for frequent upgrades, which can be costly. Look for features such as an adjustable boom and compact design that allow easy navigation in confined spaces. Industry studies suggest that construction companies utilizing adaptable machinery report a 15% increase in productivity due to reduced downtime.

Tips: Regular maintenance checks are essential to keeping your Link Belt equipment in optimal condition. Make sure to review the oil levels, hydraulic fluids, and battery health regularly. Additionally, consider investing in operator training programs. Skilled operators can maximize the efficiency of the machinery, contributing to better safety and performance on the job site. Prioritizing these factors will help ensure you make informed decisions when investing in construction equipment.

Top Link Belt Excavators for Versatile Job Performance

When it comes to excavation work in construction, selecting the right equipment is crucial for achieving efficiency and versatility on the job site. Link belt excavators are renowned for their durability and adaptability, making them an excellent choice for various applications. These machines excel in tasks ranging from digging and grading to material handling and demolition, offering operators the flexibility needed for dynamic work environments.

One of the standout features of Link belt excavators is their innovative hydraulic systems, which provide exceptional control and power delivery. This allows operators to maneuver with precision, whether they're working in tight urban conditions or more expansive rural landscapes. Additionally, these excavators come equipped with a range of attachments, enabling users to customize performance according to the specific demands of their projects. This adaptability not only enhances productivity but also helps ensure that the machinery can tackle diverse challenges encountered on the job site efficiently.

Top 10 Link Belt Excavators for Versatile Job Performance

Best Link Belt Cranes for Heavy Lifting Applications

When it comes to heavy lifting applications in the construction industry, choosing the right equipment is crucial for efficiency and safety. Link Belt cranes stand out for their quality, performance, and versatility. These cranes are engineered to handle a variety of tasks, from lifting massive steel beams to positioning heavy machinery with precision. Their robust construction ensures durability on demanding job sites, while advanced hydraulic systems provide smooth operation and impressive lifting capacities.

One of the top features of Link Belt cranes is their adaptability to various environments and challenges. With options ranging from lattice boom cranes to telescopic models, operators can select the crane that best fits their specific project requirements. Furthermore, the incorporation of innovative technology enhances the cranes’ operation, allowing for better control, stability, and safety on the job. In heavy lifting scenarios, the ability to quickly and effectively maneuver loads can significantly impact project timelines and overall success in construction endeavors.

Innovative Link Belt Attachments to Enhance Efficiency

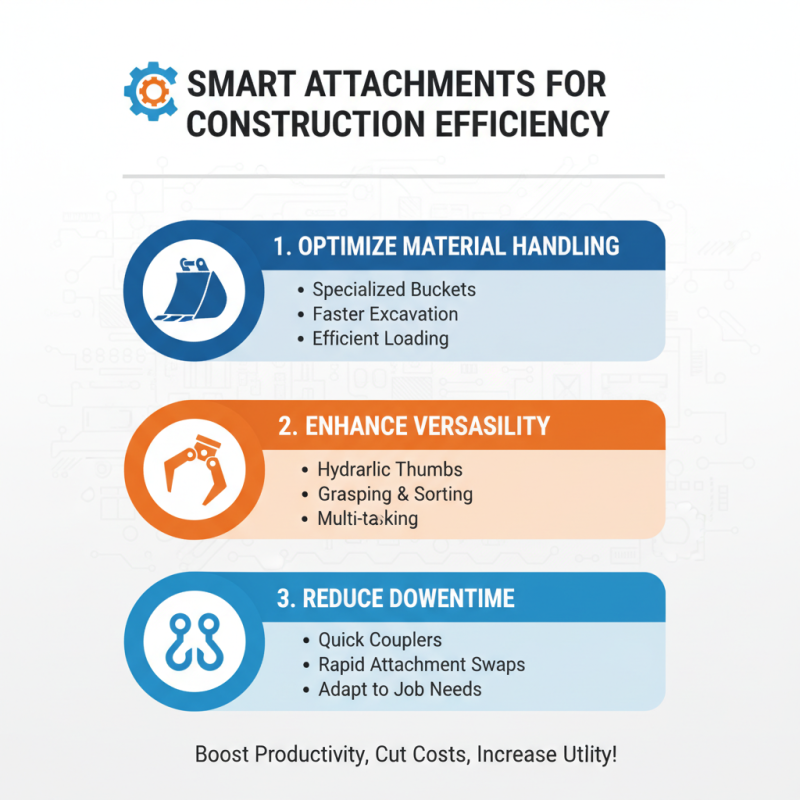

When it comes to enhancing the efficiency of your construction projects, choosing the right attachments for your equipment is crucial. Innovative attachments can significantly improve productivity, reduce operational costs, and increase the versatility of your machinery. For instance, utilizing specialized buckets can optimize material handling and excavation tasks, allowing you to switch between different functions with ease. Moreover, additional features such as hydraulic thumbs or quick couplers will enable you to adapt to a variety of job requirements promptly, maximizing the utility of your equipment.

Tips: When selecting attachments, always consider the specific demands of your project. Analyze the types of materials you’ll be working with, as well as any potential hazards in the environment that could impact performance. It’s also beneficial to look for attachments that offer multitasking capabilities, as they can save time and resources.

Another aspect to consider is regular maintenance of these innovative attachments. Keeping your equipment in top condition often extends its lifespan and maintains efficiency on the job site. Ensure that all components are checked regularly for wear and tear, and address any issues promptly to avoid costly downtimes. Investing in quality attachments along with proper care will lead to enhanced performance and efficiency in your construction needs.

Related Posts

-

10 Essential Tips to Find the Best Link Belt Dealer Near You

-

Why Investing in Forestry Equipment Is Essential for Sustainable Forest Management

-

Top 10 Tips for Buying High Quality Construction Used Equipment

-

Why Investing in Modern Construction Equipment and Machinery is Essential for Your Success

-

Top 10 Tips for Finding Reliable Link Belt Parts Dealers Near You

Subscribe to our newsletter.