Top Types of Construction Used Equipment You Should Know?

In the fast-evolving world of construction, understanding "construction used equipment" is essential. Industry expert John Smith emphasizes, “Quality used equipment can save projects from budget overruns.” His words remind us to evaluate options carefully.

Construction used equipment encompasses a wide range of machines, from bulldozers to cranes. Each item has its pros and cons. Some may depend on features, while others rely on age or condition. Not every used piece meets safety standards or performance expectations. Equipment must be inspected thoroughly before purchase.

Navigating the used equipment market can be tricky. Buyers need to be well-informed. For instance, research the equipment’s history and usage. Many assume higher prices guarantee better quality, which isn't always true. Reflecting on these aspects can lead to better decisions in future projects.

Types of Used Construction Equipment in the Market Today

The used construction equipment market has grown significantly. According to industry reports, the global market for used construction equipment reached approximately $58 billion in 2022. This trend highlights the importance of understanding various types of equipment available for buyers.

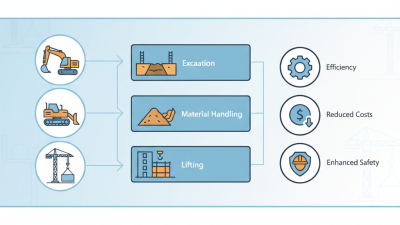

Excavators dominate the used market. They account for nearly 30% of sales. This is due to their versatility in various projects. Wheel loaders follow closely, making up about 20% of the market. Their ability to handle materials efficiently is invaluable in construction. Additionally, bulldozers are essential for land clearing and grading. They still remain popular among contractors looking for reliable equipment.

However, purchasing used machinery can be challenging. Buyers must focus on the equipment's history and condition. Many machines may have hidden issues. A recent survey showed that around 40% of used equipment owners reported unexpected repairs within the first year. This statistic emphasizes the need for thorough inspections before buying. Balancing cost with quality becomes crucial in the decision-making process.

Factors to Consider When Buying Used Construction Equipment

When considering buying used construction equipment, certain factors play a crucial role. One major aspect is the equipment's age and usage history. According to a recent report from the Association of Equipment Manufacturers, equipment that is older than five years can face higher maintenance costs. It's wise to thoroughly check the machinery's service records. An inspection report should unveil hidden issues.

Another important factor is the equipment's condition. Inspecting for wear and tear can save time and costs in the long run. Basic checks include assessing the hydraulic system and the engine condition. A machinery survey from the Equipment Watch indicates that nearly 30% of used equipment fails to meet buyer expectations due to inadequate pre-purchase inspections. This can lead to costly repairs.

Additionally, understanding the equipment's resale value is critical. Market trends show that older machines tend to depreciate faster. A construction industry analysis revealed that some models depreciate by as much as 50% within the first five years. This highlights the need for careful evaluation before making a decision. A wise investment considers not just the purchase price but future expenses.

Advantages of Purchasing Used Equipment Over New Equipment

When considering construction equipment, the choice between used and new can be challenging. Used equipment often comes with a lower price tag. This makes it more accessible for smaller companies. Many businesses can invest in quality machinery without breaking the bank. One key reason to buy used is the depreciation factor. New equipment loses value quickly, while used items retain their worth better.

In addition, buying used allows for more flexibility in budgeting. Companies might save enough to purchase additional tools or hire more workers. This can lead to increased productivity. On the flip side, it is essential to check the equipment's condition carefully. Some used machines might have hidden flaws. Skipping inspections can lead to costly repairs later on. Weighing the pros and cons is crucial. It's not just about price; reliability matters too.

Maintenance Tips to Extend the Life of Used Construction Gear

Maintaining used construction equipment is crucial for longevity. Regular inspection can prevent major issues. Check hydraulic systems, filters, and belts frequently. Look for any signs of wear and tear, as small problems can escalate quickly. Daily upkeep can save money in the long run.

Cleaning your equipment regularly is essential. Removing mud and debris helps prevent rust and corrosion. Pay attention to the undercarriage, as it often accumulates dirt. Keep the machine's surfaces protected with appropriate coatings. Neglecting basic cleaning routines can lead to bigger maintenance challenges.

Lubrication is another key aspect. Use the right lubricants according to specifications. Regularly grease moving parts to minimize friction and wear. It’s easy to forget this step when busy, but it’s vital. Scheduled maintenance can easily slip through the cracks. Being diligent can significantly extend the life of your gear.

Top Types of Construction Used Equipment

Market Trends Affecting Prices of Used Construction Equipment

The used construction equipment market is influenced by various trends. One significant factor is the demand for more sustainable machinery. As construction companies aim for green practices, they seek equipment that aligns with these goals. This shift can impact pricing significantly. Buyers might notice rising prices for eco-friendly machinery as supply dwindles.

Another trend is the rise of technology in construction. Advanced features in used equipment are becoming more sought after. This means older models may lose value faster as new technology enters the market. However, not all buyers are ready to adopt these changes. Some prefer reliability over innovation, creating a mixed demand landscape.

Economic fluctuations also play a role. When the economy slows, construction projects may halt. This results in an oversupply of equipment, driving prices down. Conversely, in a booming economy, prices may spike. It’s crucial for buyers and sellers to stay informed about these trends. Understanding the market dynamics can lead to better decisions in purchasing used equipment.

Related Posts

-

Top 10 Tips for Buying High Quality Construction Used Equipment

-

What is Construction Equipment Machine? Types, Uses, and Benefits Explained

-

What is a Link Belt Parts Dealer and How to Choose One?

-

What is Used Link Belt Parts and How to Find Them?

-

2026 Top Heavy Machinery Dealer Trends and Innovations?

-

Why Choose Link Belt Company for Your Material Handling Solutions?

Subscribe to our newsletter.